Chemical Analysis

|

Composition |

Value |

|

SiO2 |

≥72% |

|

Fe2O3 |

≤0.5% |

|

CaO |

≤1.0% |

|

Al2O3 |

≥23% |

|

MgO |

≤1.0% |

|

Other |

2% |

Physical Property

|

Index |

Value |

|

Specific gravity(g/cm3) |

2.5 |

|

Water absorption (wt%) |

≤0.5 |

|

Acid resistance (wt%) |

≥99.5 |

|

Loss in burn (wt%) |

≤5.0 |

|

Max. Operating Temp.(℃) |

800 |

|

Crush strength (Mpa) |

≥130 |

|

Moh’s Hardness(Scale) |

≥7 |

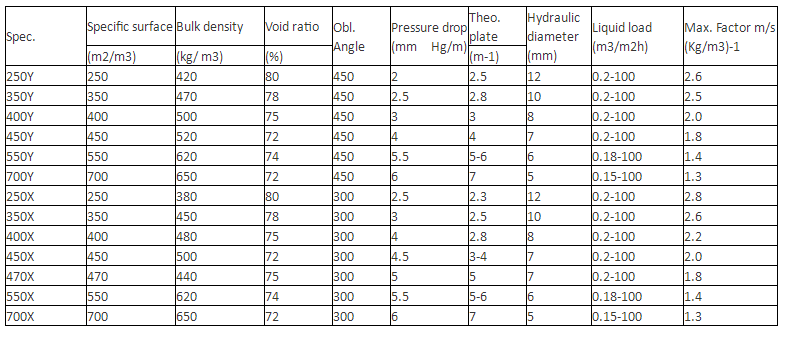

Geometric Characteristic

Advantage

● High capacity. New tower design may reduce diameter, while renovate old towers may increase capacity significantly.

● High separation efficiency. Since it has much larger specific surface area compared to random packing.

● Low pressure drop, which leads to reduce energy consumption largely.

● Large flexibility, and scale effect is not obvious.

● Suitable for all tower diameters.

● Strong resistance to corrosion of acid and alkali, especially to H2S, naphthenic acid and Cl- .

Applications

● Rectifying organic halide.

● Rectifying and absorbing some corrosive mixtures, which are definitely regulated in pressure drop and theoretic plate number.

● Applied in some towers that contain a large quantity of natural media used to absorb nitric acid and concentrated sulfuric acid, as well as for purifying the air in chemical plants.

● Operating in vacuum conditions at a bottom absolute pressure of 100pa.

● Used in heat exchanger and demisting, or as a catalyst carrier.